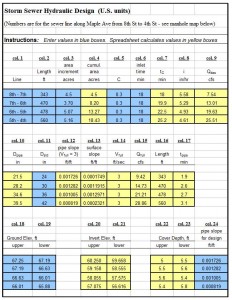

Where to Find Storm Sewer Hydraulic Design Spreadsheets

For storm sewer hydraulic design spreadsheets, click here to visit our spreadsheet store. Read on for information about the use of Excel spreadsheets for storm sewer hydraulic design calculations with the Manning Equation.

One part of storm sewer hydraulic design is determination of the design pipe diameter and sewer slope for the storm sewer pipe between adjacent manholes. Although storm sewers are circular pipes, the storm water typically flows under gravity, rather than as pressure flow, so the Manning equation for open channel flow can be used for the calculations. A storm sewer hydraulic design spreadsheet typically makes hydraulic calculations for full pipe flow. For full pipe flow, the hydraulic radius becomes: R = A/P = (πD2/4)/(πD) = D/4.

The Manning Equation in a Storm Sewer Hydraulic Design Spreadsheet

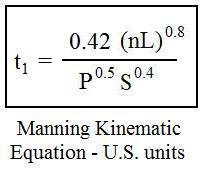

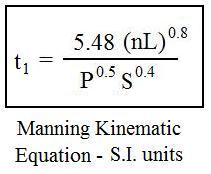

The general form of the Manning equation in terms of velocity is: V = (1.49/n)(R2/3)(S1/2) for U.S. units and V = (1.0/n)(R2/3)(S1/2) for S.I. units. As noted above, R = D/4 for full pipe flow, so the Manning equation in U.S. units becomes V = (1.49/n)[(D/4)2/3](S1/2) -U.S. units or V = (1.0/n)[(D/4)2/3](S1/2) – S.I units, for full pipe, gravity flow in a storm sewer pipe. The parameters in the equations are as follows:

- V is the flow velocity in the pipe (ft/sec – U.S. and m/s – S.I.).

- n is the Manning roughness coefficient, an empirical, dimensionless constant.

- D is the pipe diameter (ft -U.S. and m – S.I.).

- S is the pipe slope, which is dimensionless.

The volumetric flow rate is related to the other parameters through the equation Q = VA or, for a circular pipe flowing full: Q = (πD2/4)V, where Q will be in cfs for U.S. units or m3/s for S.I. units.

Calculation of Diameter and Slope with a Storm Sewer Hydraulic Design Spreadsheet

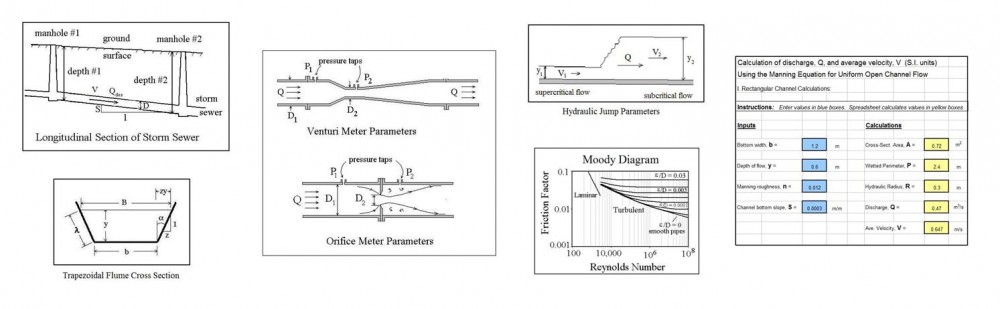

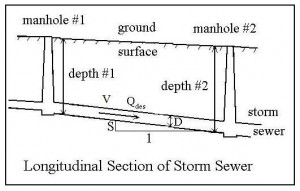

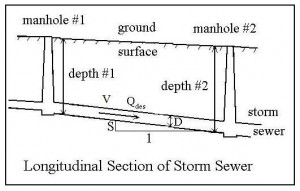

The required diameter and slope for the length of storm sewer between two manholes can be calculated with a storm hydraulic sewer design spreadsheet using the equations presented in the last section (Mannings equation and Q = VA) together with the typical design criteria that 1) the full pipe flow rate that the pipe can carry must be at least equal to the design peak storm water runoff rate to the inlet for that section of storm sewer and 2) the full pipe velocity must be equal to or greater than a specified minimum velocity. The diagram above shows a sectional view of a storm sewer pipe between two manholes and the parameters being discussed here. The calculation procedure is illustrated by the example in the next section.

The required diameter and slope for the length of storm sewer between two manholes can be calculated with a storm hydraulic sewer design spreadsheet using the equations presented in the last section (Mannings equation and Q = VA) together with the typical design criteria that 1) the full pipe flow rate that the pipe can carry must be at least equal to the design peak storm water runoff rate to the inlet for that section of storm sewer and 2) the full pipe velocity must be equal to or greater than a specified minimum velocity. The diagram above shows a sectional view of a storm sewer pipe between two manholes and the parameters being discussed here. The calculation procedure is illustrated by the example in the next section.

Example Storm Sewer Hydraulic Design Calculations

Problem Statement: For a section of storm sewer between two manholes, the design flowrate is: Qdes = 6.4 cfs. The required minimum full pipe storm water velocity is: V min= 3 ft/sec. The Manning roughness coefficient (concrete pipe) is: n = 0.011. Find a standard pipe diameter and sewer slope that will meet the two criteria: Qfull > Qdes and Vfull > Vmin for this section of storm sewer pipe.

Problem Solution: First the pipe diameter needed for a full pipe velocity of 3 ft/sec at design flow rate will be calculated using the equation: Q = VA. Then the Manning equation will be used to calculate the sewer slope needed to give full pipe velocity equal to 3 ft/sec with the next larger standard pipe size.

Step 1: The equation, Q = VA becomes: Qfull = Vfull(πD2/4). Substituting known values for Qfull and Vfull, the equation becomes: 6.4 = 3(πD2/4). Solving for D gives: D = 1.65 ft = 19.8 in. From the list of standard storm sewer pipe sizes in the next section it can be seen that the next standard size larger than 19.8 inches is 21 “, so that will be used for the diameter.

The Manning equation will then be used to calculate the slope for D = 21 in. = 1.75 ft, and V = 3 ft/sec. The Manning equation is: V = (1.49/n)[(D/4)2/3](S1/2). Substituting values for V, D, and n gives: 3 = (1.49/0.011)[(1.75/4)2/3](S1/2). Solving this equation for S gives: S = 0.00148.

Thus, the solution is: D = 21″, S = 0.00148. These values of D and S will give Qfull > 6.4 cfs, because Qfull = 6.4 cfs for Vfull = 3 ft/sec and D = 19.8″. With D = 21 ” and V = 3 ft/sec, Qfull must be greater than 6.4 cfs. The equation Q = (πD2/4)V can be used to check this.

Standard Pipe Sizes

Standard U.S. pipe sizes in inches for most types of pipe used as storm sewers: 4, 6, 8, 10, 12, 14, 16, 18, 21, 24, 27, 30, 33, 36, 39, 42, 48, 54, 60

Standard S.I. pipe sizes in mm for most types of pipe used as storm sewers: 100, 150, 200, 250, 300, 350, 400, 450, 500, 600, 650, 700, 750, 800, 850, 900, 950, 1000, 1050

Use of Excel Spreadsheets for Storm Sewer Design Calculations

For information on making storm sewer calculations with Excel spreadsheets, see the related article: “Excel Spreadsheets for Storm Sewer Hydraulic Design.” For low cost, easy to use spreadsheets for several types of storm water calculations, including storm sewer hydraulic design, click here to visit our spreadsheet store.

References

1. Bengtson, Harlan H., Hydraulic Design of Storm Sewers, Including the Use of Excel, an online, continuing education course for PDH credit.

2. McCuen, Richard H., Hydrologic Analysis and Design, 2nd Ed, Upper Saddle River, NJ, Prentice Hall, 1998.

3. Steele, E.W. and McGhee, T.J., Water Supply and Sewerage, New York, NY, McGraw-Hill Book Co, 1979.

4. Bengtson, Harlan H., Hydraulic Design of Storm Sewers with a Spreadsheet,” an Amazon Kindle ebook

5. Bengtson, Harlan H., “Hydraulic Design of Storm Sewers with Excel” an online blog article.