Where to Find an API 570 Piping Inspection Calculations Spreadsheet

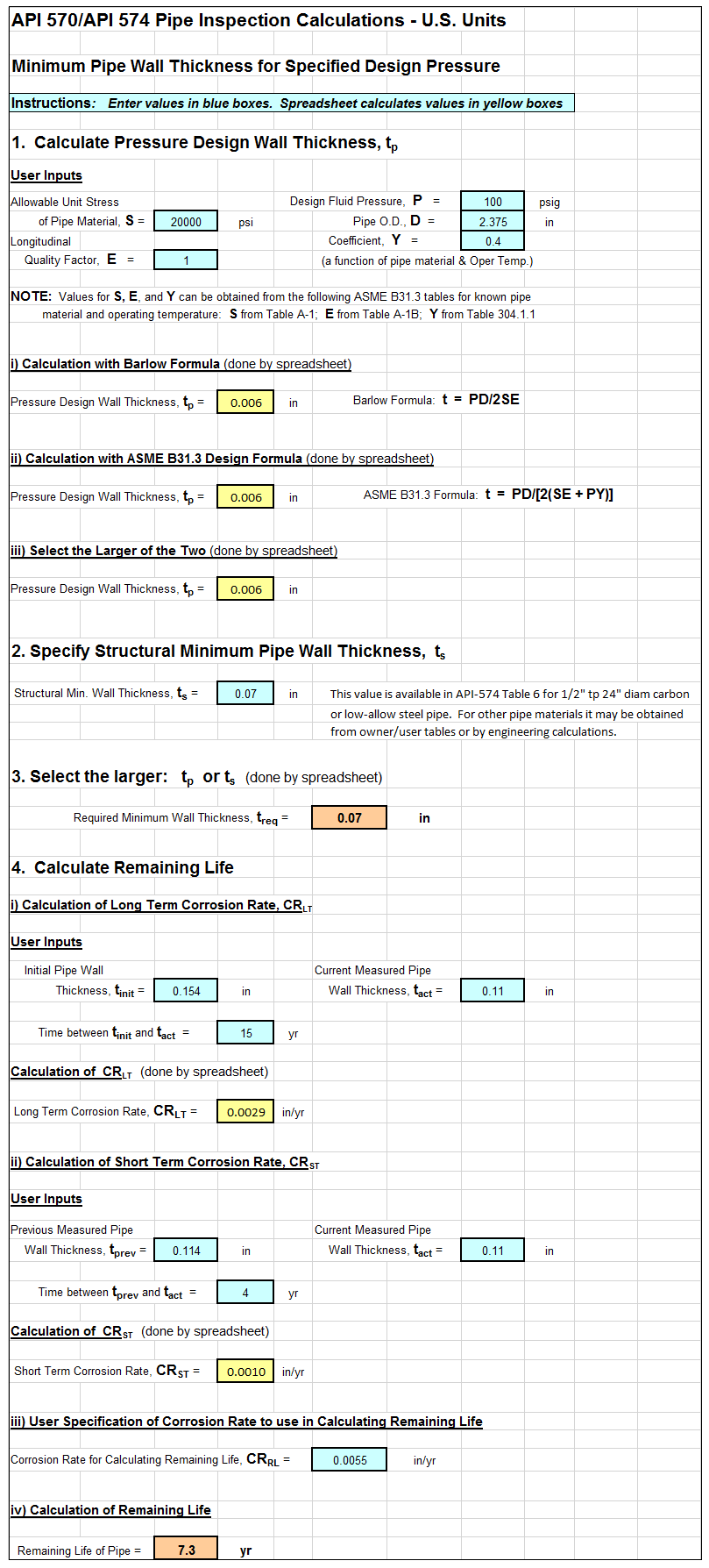

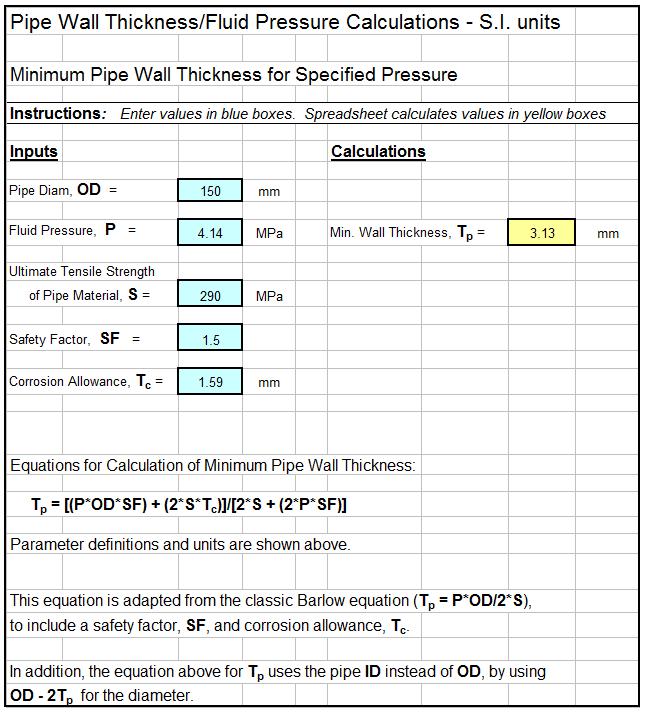

To obtain an API 570 Piping Inspection Calculations spreadsheet, click here to visit our spreadsheet store. This Excel spreadsheet is intended for making piping inspection calculations from API 570 and API 574.. You can buy a convenient API 570 piping Inspection calculations spreadsheet for a very reasonable price. This spreadsheet calculates required minimum pipe wall thickness, long term corrosion rate, short term corrosion rate, remaining life, and maximum allowable working pressure (MAWP). It is available in either U.S. units or S.I. units. Read on for information about using an API 570 piping inspection calculations spreadsheet.

Formulas for API 570 Piping Inspection Calculations Spreadsheet

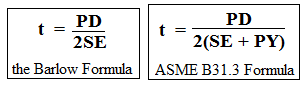

The required minimum wall thickness for piping being inspected must be the greater of the calculated pressure design wall thickness and the structural minimum wall thickness. The pressure design wall thickness is sometimes calculated with the Barlow formula and sometimes it is calculated with the ASME B31.3 formula. Both are shown below.

In the Barlow formula and the ASME B31.3 formula, P is the design fluid pressure in psig, D is the pipe O.D. in inches, S is the allowable unit stress of the pipe material in psi, E is a longitudinal quality factor, and Y is a coefficient that is a function of the pipe material and the operating temperature.

In the Barlow formula and the ASME B31.3 formula, P is the design fluid pressure in psig, D is the pipe O.D. in inches, S is the allowable unit stress of the pipe material in psi, E is a longitudinal quality factor, and Y is a coefficient that is a function of the pipe material and the operating temperature.

The structural minimum wall thickness is available in API 574 Table 6 for some pipe materials. The required minimum pipe wall thickness is the greater of the calculated pressure design wall thickness and the structural minimum wall thickness.

The long term corrosion rate and short term corrosion rate are calculated from values for the current measured pipe wall thickness, a previous pipe wall thickness or the initial pipe wall thickness and the time between the two. The remaining life of the pipe is calculated as the difference between the current measured pipe wall thickness minus the required minimum pipe wall thickness divided by the corrosion rate.

The maximum allowable working pressure for a pipe is calculated from the formula:

MAWP = 2SEt/D

In this formula, S, E, and D are as defined above and t is the measured pipe wall thickness in inches.

Example API 570 Piping Inspection Calculations Spreadsheet

An example API Piping Inspection Calculatons spreadsheet is partially shown in the image below. This Excel spreadsheet can be used to calculate the required minimum pipe wall thickness, corrosion rate, remaining life, and maximum allowable working pressure (MAWP). This Excel spreadsheet, as well as others for pipe flow calculations, is available in either U.S. or S.I. units for a very reasonable price in our spreadsheet store.

1. American Piping Institute, AP! 570, Piping Inspection Code: In-service Inspection, Rating, Repair, and Alteration of Piping Systems, 3rd Ed, Nov, 2009

2. American Piping Institute, API 574, Inspection Practices for Piping System Components, 3rd Ed, Nov, 2009.

3. Bengtson, Harlan H., Spreadsheet for API Piping Inspection Calculations, an informational blog article at www.EngineeringExcelTemplates.com